There are so many co2 laser tubes available

in the market and everybody is saying that our co2 laser tube is the best

quality. I am sure you are tired of this and sometimes don’t know what to do.

Should I buy the cheapest one? Anyway, it is not expensive, it’s not a big deal

even the quality is bad. How about the most expensive one? I don’t want to

waste my money and time, just need the right thing. Or maybe I should choose

the middle-price rated one? It seems more price-competitive. I am sure you went

through one of those situations, maybe more than this? SPT laser is here to guide

you how to tell good laser tube by some simple means. And also this is how SPT

laser picks good laser tubes when sending your laser tube orders.

First you have to install your laser tube

well, connect it to the water chiller (chiller pump), and get it wire

connected. Then do the following steps.

1.

Get laser spot. Set the current at 10mA,

do the test as following steps at 0.5~2m away from the laser tube negative end:

Fire a spot on the card board,

and check the shape of the spot.

A: The spot is a

very good solid round, the laser tube is good.

B: The spot is

an oval, please check if the laser tube is put on the tube support at the best

laser tube support point.

C: The spot is a

circle, please check if the tube supports is at the best laser tube support

point, and the testing distance is between 0.5 and 2.0m. If the support point

and test distance both are right, the laser tube is bad.

Good laser spot Bad laser spot

Fire a spot on thermal

paper,

A: The inner and outline of the spot is parallel regular

circle, the laser tube is good.

B: The inner and outline of the spot is irregular, the

laser tube is bad.

Good laser spot

Bad laser spot A Bad laser spot B

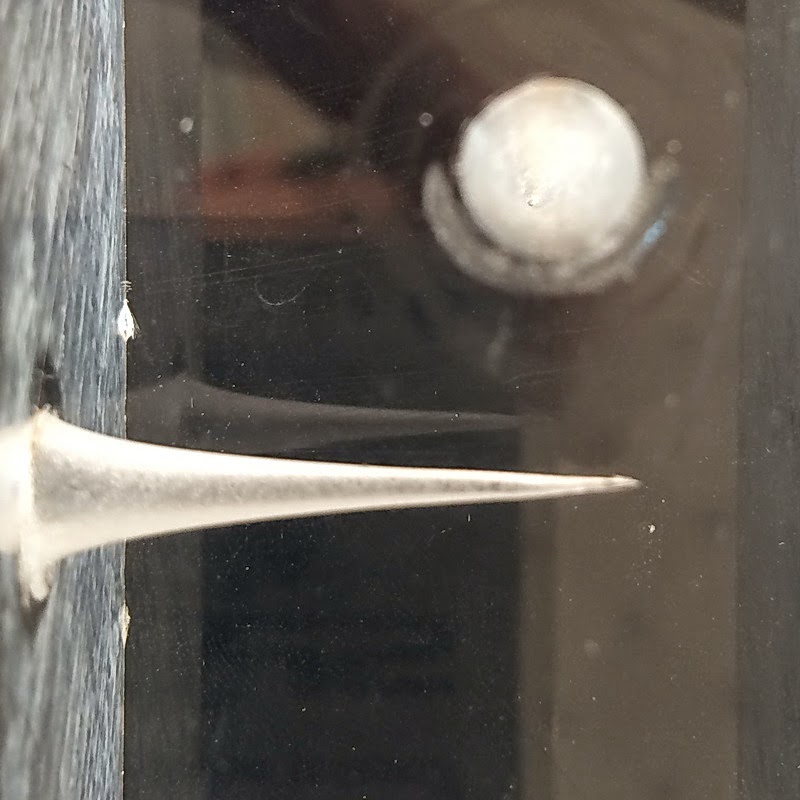

Laser spot mode test: Put a 40mm thick acrylic at the point where is

1.2m~1.5m away from the laser tube negative end.

Adjust the current to 20mA~25mA, push the laser button, let the

laser fire on the acrylic for seconds. You will get a conic hole on the acrylic.

If the conic is very round and regular, the laser tube is good.

Fire a spot on acrylic:

A, The laser

spot is a solid circle, the laser tube is good.

B, The laser

spot is an irregular round, and the tube supports are at right support point,

test distance is also correct, the laser tube is bad.

2.

Laser power test: Under rated current,

if the laser tube peak power is more than its rated power by 10W, the laser

tube is good. Those are the laser tube model and basic parameters of SPT laser

tube for your reference:

Item

|

Product

|

Series

|

Model

|

Current

( mA)

|

Rated Power

(Watt)

|

Peak Power

( Watt)

|

Length

(mm)

|

Pipe diameter

(mm)

|

Catalytic

(Y/N)

|

A001

|

Co2 laser tube

|

G series

|

G40

|

15

|

40

|

50

|

700

|

50

|

N

|

A002

|

Co2 laser tube

|

G50

|

15

|

50

|

60

|

1000

|

50

|

N

|

|

A003

|

Co2 laser tube

|

G60

|

20

|

60

|

70

|

1200

|

50

|

N

|

|

A004

|

Co2 laser tube

|

G70

|

20

|

60

|

70

|

1250

|

55

|

N

|

|

A005

|

Co2 laser tube

|

G80

|

20

|

80

|

100

|

1600

|

60

|

N

|

|

A006

|

Co2 laser tube

|

C series

|

C40

|

15

|

40

|

50

|

800

|

80

|

Y

|

A007

|

Co2 laser tube

|

C50

|

15

|

50

|

70

|

1000

|

50

|

Y

|

|

A008

|

Co2 laser tube

|

C60

|

20

|

60

|

80

|

1200

|

50

|

Y

|

|

A009

|

Co2 laser tube

|

C70

|

20

|

60

|

80

|

1250

|

55

|

Y

|

|

A010

|

Co2 laser tube

|

C80

|

25

|

100

|

120

|

1600

|

60

|

Y

|

|

A011

|

Co2 laser tube

|

C90

|

25

|

90

|

100

|

1250

|

80

|

Y

|

|

A012

|

Co2 laser tube

|

C100

|

25

|

100

|

130

|

1450

|

80

|

Y

|

|

A013

|

Co2 laser tube

|

C130

|

25

|

130

|

150

|

1650

|

80

|

Y

|

|

A014

|

Co2 laser tube

|

C150

|

30

|

150

|

180

|

1850

|

80

|

Y

|

|

A015

|

Co2 laser tube

|

S series

|

S90

|

25

|

90

|

100

|

1250

|

80

|

Y

|

A016

|

Co2 laser tube

|

S100

|

25

|

100

|

130

|

1450

|

80

|

Y

|

|

A017

|

Co2 laser tube

|

S130

|

25

|

130

|

150

|

1650

|

80

|

Y

|

|

A018

|

Co2 laser tube

|

S150

|

30

|

150

|

180

|

1850

|

80

|

Y

|

没有评论:

发表评论