We all know that the co2 laser has been widely used for cutting/ engraving acrylic,

cloth, leather, wood and other non-metal materials. Due to high efficiency and

high precision of process, co2 laser is very popular in today's advertising

industry as well as clothing, footwear and other industries. In fact, co2 laser

also contributes a lot to the packaging industry, and the packaging industry is

one of the earliest industries adopt co2 laser into production.

1. Corrugated case printing plate

The most common packaging is corrugated case in the printing and packaging industry. Corrugated boxes can be divided into two categories, one is the sales package, and the other is the transport package. Sales package is generally for inner-packing, used in the sales process to meet with consumers, such as color box, white box, gift boxes. Transport packages are outer-packing, and its main role is to facilitate the storage and transportation, such as cardboard boxes, corrugated boxes and so on.

Laser engraving machine achieves carving by doting on material surface, has a born advantage in grayscale performance. So in the carving design, gray level appearance form is very popular to reduce the coloring process to cut costs; on the one hand, it enriches the carving performance, increases graphical levels. Meanwhile, the cost of printing plate for engraving on paper packaging materials made by co2 laser is very low, only a quarter of resin version, so co2 laser engraving plate is commonly used as corrugated packaging printing mode in packing industry nowadays.

1. Corrugated case printing plate

The most common packaging is corrugated case in the printing and packaging industry. Corrugated boxes can be divided into two categories, one is the sales package, and the other is the transport package. Sales package is generally for inner-packing, used in the sales process to meet with consumers, such as color box, white box, gift boxes. Transport packages are outer-packing, and its main role is to facilitate the storage and transportation, such as cardboard boxes, corrugated boxes and so on.

Laser engraving machine achieves carving by doting on material surface, has a born advantage in grayscale performance. So in the carving design, gray level appearance form is very popular to reduce the coloring process to cut costs; on the one hand, it enriches the carving performance, increases graphical levels. Meanwhile, the cost of printing plate for engraving on paper packaging materials made by co2 laser is very low, only a quarter of resin version, so co2 laser engraving plate is commonly used as corrugated packaging printing mode in packing industry nowadays.

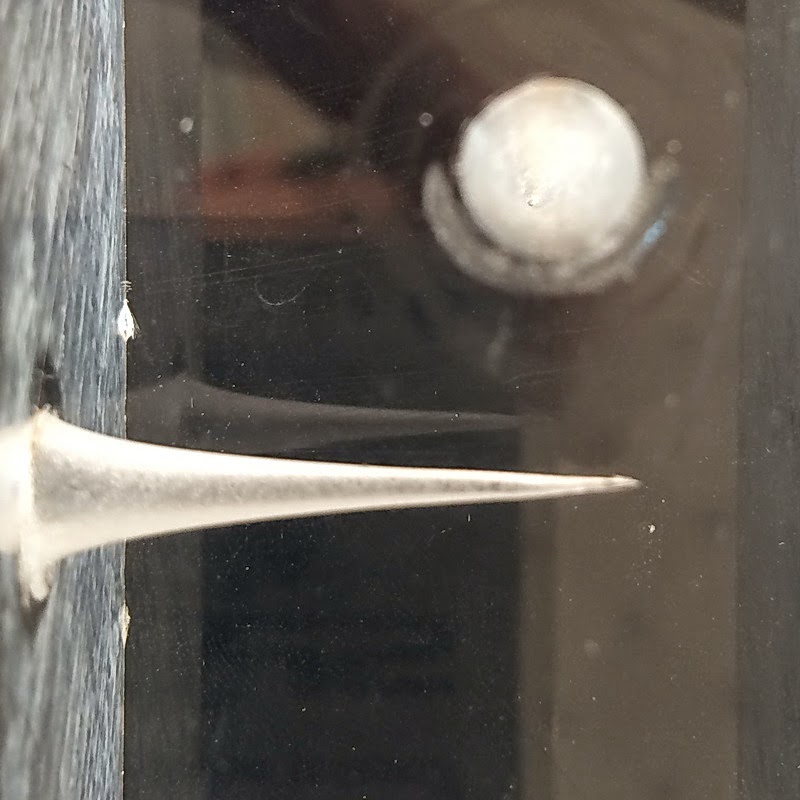

2. Die-cutting board making

Die-cutting is cutting process crates, boxes before molding, with the cutting knife combined to die - according to product design requirements, under pressure, and will print or other plate-blank roll and cut into desired shapes or cuts in the molding process. With the rapid development of world economy, the increased demand packing boxes, plate-making process improvement, higher quality requirements, the product of small batches of multi-volume, problems about shorten delivery time and cost increases and other issues show up, the traditional manually cutter template box making process can’t meet these market needs and solve coming problems. Because of high efficiency, high accuracy, low cost, flexible production and operability, laser processing rapidly rises up and being widely used in the packaging industry. Co2 laser die-cutting machine ablates die-board in high depth with its high heat to get cutter point. This makes die-cutting board has slotted collimation, consistent slit width. Co2 laser die-cutting process is fully automated operation, has fast delivery, high efficiency, low cost, it is the best alternative to manual work production of precision cutting board.

In addition, co2 laser processing also affects and enriches the diversity and practicality on other aspects in packing industry. Co2 laser used to mark products, logos, bar codes, or other markings printed on the product packaging, which enhances the richness of information on package, to better highlight the brand. Other important applications include the plastic packaging punch to extend the shelf life of food perishable; or in the paper packaging, cardboard, or plastic wrap advance left tear, these applications are extremely convenient for consumers as well as bring more invisible benefits for suppliers. We believe that with the rapid changes in technology, co2 laser will surprise us more with its applications in packing business.