Co2 laser spare parts professional manufacturer with ISO9001, CE & FDA certificate. Mainly supply glass co2 laser tube (30w~150w), co2 laser focus lens, co2 laser mirror, power supply, linear guide rail.

2015年11月30日星期一

2015年9月13日星期日

2015年6月25日星期四

Careless, really blind --- Laser Safety Basics

Careless, really blind --- Laser Safety Basics

First, the domestic part of the standard laser safety aspects related to1. "GB7247.1-2012 Safety of laser products Part 1: Equipment classification, requirements" ("Safety of laser products-Part 1: Equipment classification andrequirements", idt "IEC60825-1: 2007 Safety of laserproducts - Part 1: Equipment classification and requirements ", identical with" IEC60825-1: 2007 Safety of laser products - Part 1: Equipment classification and requirements ")

2. "GB / T 15706.1-1995 Safety of machinery - Basic concepts, general principles for design - Part 1: Basic terminology, methodology"

3. "GB / T 15706.2-1995 Safety of machinery - Basic concepts, general principles for design - Part 2: Technical principles and specifications"

4. "GB / T 5226.1-2002 Safety of machinery - Electrical equipment - Part 1: General requirements"

5. "GB18490-2001 laser processing machinery safety requirements" (eqv "ISO 11553: 1996 Safety of machinery - Laser processing machines- Safety requirements")

6. "Electrical Safety GB10320-1995 laser equipment and facilities" (eqv "IEC 820: Electrical safety of laser equipment and installations")

7. "GBZ2.2-2007 Workplace Hazardous Occupational Exposure Limits Part 2: physical factors" (related to the laser radiation section)

Second, the maximum permissible exposure (MPE), accessible emission limit (AEL)

The maximum permissible exposure (MPE), accessible emission limit (AEL) is based on the classification of laser products.

The maximum permissible exposure (Maximum Permissible Exposure) is normally illuminated by the laser body does not produce adverse consequences of laser radiation levels.

MPE level can be without means or after prolonged eye or skin by irradiating the maximum radiation level in injury, which the laser radiation wavelength, pulse width or duration of irradiation, due to the dangerous state of biological tissue and exposed the 400nm ~ 1400nm visible and infrared laser radiation in the retinal image size and so on.

Accessible Emission Limit (Accessible Emission Limit, abbreviated AEL), the maximum allowable emission levels within a given category. It is usually obtained from the maximum allowable exposure (MPE).

Third, the classification of laser products

To facilitate laser product safety management, countries are to develop the appropriate classification standard for laser products. Our standard is "GB7247.1-2012 Safety of laser products Part 1: Equipment classification, requirements."

Since the wavelength of the laser beam energy range and pulse characteristics may involve a wide range, so use the degree of harm is very poor. According to the degree of harm, laser products are divided into classes 1, 1M, Class 2, 2M class, 3R class, 3B Class 4 category, a total of seven categories. The minimum degree of harm which Class 1, four categories of products the greatest hazard.

It is noteworthy that, it was in reference to laser products, they tend to use two, four other words, incorrect, should be Class 2, Class 4.

A) Class 1

Definition: During operation, in the corresponding emission wavelength and duration of human contact must not exceed a Class 1 laser radiation can reach emission limit (AEL) laser products.

Description: during use, including long time depending on the speed of light directly, even when using the optical observation instrument eye loupe with binoculars or binoculars by laser irradiation is still safe laser. Class 1 also includes a fully enclosed shield high power laser products, the use of the reach of potentially harmful radiation (embedded laser products), emit visible radiation energy beam within a Class 1 laser products may still produce stunning visual visual effects, especially in low light environments.

B) 1M class

Definition: in 302.5nm ~ 4000nm wavelength range, during the work, in the corresponding emission wavelength and duration of human contact up to laser radiation emission must not exceed Class 1 up to the limit (AEL) laser products.

Description: Includes the naked eye, in use for a long time directly into the beam, as the laser is safe, when using two optical viewing instruments (eye loupes or binoculars binoculars) one under the following conditions, exposure over MPE, and could cause Eye damage:

a) For the divergence of the laser beam, if the users in order to gather (collimation) the speed of light within an optical assembly is placed in a distance of 100mm from the light source;

b) For the collimated laser beam having a diameter larger than the diameter of the conditions specified measurement 3.

Class 1 laser wavelength range, limited to optical instruments translucent glass optical materials particularly good spectrum, namely between 302.5mm-4000mm, emit visible radiation energy beam Class 1M laser products may still produce stunning endoscopy visual effects, especially in low light environments.

C) Class 2

Definition: in a 400nm ~ 700nm wavelength range, during the work, in the corresponding emission wavelength and duration of human contact up to laser radiation must not exceed Class 2 reach emission limit (AEL) laser products.

Description: The product range of the laser emission wavelength of 400nm-700nm of visible radiation. Instantaneous irradiation is safe, but the laser beam may be interested in watching hazardous. Time reference for the 0.25s, this category is defined as proprietary, and assuming for the moment slightly longer time exposure, the risk of injury is low.

The following factors help to prevent reasonably foreseeable conditions of injury:

- Irradiation unconscious rarely reflect worst-case conditions, such as beam alignment of the pupil, the eye adapting the worst case;

--MPE Inherent safety margin, AEL its basis;

- To avoid bright light of natural behavior.

Compared with 2M, Class 2 in the use of optical instruments does not increase the risk of eye injury.

However, Class 2 laser beam can cause product after dazzling, flash blindness and visual images, especially in low light environments. Temporary visual disturbances or frightened reaction caused by indirect general safety issues. If the user demanding security operations, such as operation of machines, work at height, high voltage work environment or while driving, visual disturbances may need special attention.

Users do not stare into the laser beam to be labeled in accordance with instructions, that by removing the head or eyes closed to complete the active defense reaction and avoid sustained intentional beam eye.

D) 2M category

Definition: in a 400nm ~ 700nm wavelength range, during the work, in the corresponding emission wavelength and duration of human contact up to laser radiation must not exceed Class 2 reach emission limit (AEL) laser products.

Description: This type of laser products emit visible laser beam, only the naked eye safe short-term irradiation. In the following conditions, the use of two optical viewing instruments (eye loupes or binoculars) by irradiation of eye damage can occur:

a) For the divergence of the beam, if the user to focus (collimated) beam and an optical assembly is placed within a distance of 100mm from the light source;

b) For a collimated beam having a diameter larger than the diameter measurement of the third predetermined conditions.

However, 2M laser products after dazzling beam may cause flash blindness and visual images, especially in low light environments. Temporary visual disturbances or frightened reaction caused by indirect general safety issues. If the user demanding security operations, such as operation of machines, work at height, high voltage work environment or while driving, visual disturbances may need special attention.

Users do not stare into the laser beam to be labeled in accordance with instructions, that by removing the head or eyes closed to complete the active defense reaction and avoid sustained intentional beam eye.

E) 3R class

Definition: During the period of work, personnel exposure to laser radiation is allowed to exceed Class 1 and Class 2 up emission limit (AEL), but in any emission duration and wavelength, personnel exposure to laser radiation must not exceed Class 3R and Class 3B each up emission limit (AEL) laser products.

Description: MPE may exceed the radiation-emitting laser products when such apparent in the direct beam, but in most cases is relatively low risk of injury. Because of AEL Class 3R only 2 categories (visible laser beam) AEL or Class 1 (not visible beam) five times the AEL. The risk of damage increases with the irradiation duration and enhanced intentional eye exposure is dangerous. Because of the lower risk, the applicable manufacturing requirements and user controls less than the Class 3B.

Limited risk because:

- Irradiation unconscious rarely reflect worst-case conditions, such as beam alignment of the pupil, the eye adapting the worst case;

--MPE Inherent safety margin;

- Visible radiation under a bright light, and far-infrared radiation on the cornea heated natural avoidance behavior.

After 3R laser products category in the visible range of the laser beam can cause glare, flash blindness and visual images, especially in low light environments. Temporary visual disturbances or frightened reaction caused by indirect general safety issues. If the user demanding security operations, such as manipulation of the machine working in high places, high voltage work environment or while driving, visual disturbances may need special attention.

Class 3R lasers should only occur in the unlikely case of a direct beam depending on use;

F) 3B class

Definition: During the period of work, personnel exposure to laser radiation is allowed to exceed Class 1 and Class 2 up emission limit (AEL), but in any emission duration and wavelength, personnel exposure to laser radiation must not exceed Class 3R and Class 3B each up emission limit (AEL) laser products.

Description: This type of laser beam eye exposure occurs in the product (that is, within NOHD), short-term irradiation include accidental, usually harmful.

Diffuse observe generally safe. AEL of Class 3B close 3B laser can cause minor skin damage, and even the risk of ignition of combustible materials. However, this occurs only to a very small diameter beam or focusing.

Note: There is some theoretical (but rarely) viewing conditions, there may be more than observe diffuse MPE. For example, having a power close AEL of Class 3B laser, observe really diffuse visible radiation, observation time than 10s, between the observation point and diffuse corneal surface at a distance of less than 325px, under the above conditions, will diffuse over MPE.

G) 4 class

Definition: human contact Class 3B laser radiation allowed to exceed the accessible emission limit (AEL) laser products.

Description: This type of laser products, endoscopy and skin irradiation beams are dangerous, watch the diffuse reflection may be dangerous, such lasers are often cause a fire.

Fourth, the spectrum

Fiber laser for laser cutting (wavelength 1.06μm) and CO2 laser (wavelength 10.6μm), are located in IR (infrared) region.

5. the effect of eyedifferent wavelengths of laser

CO2 laser wavelength of 10.6 μm, belongs to the infrared light is absorbed by the cornea, it can burn the cornea.

CO2 laser will be absorbed by the cornea

Fiber laser wavelength 1.064 μm, belonging to the near-infrared light can pass through the cornea (Cornea) and lens (Lens), and then focused onto the retina (retina) on, and burns the retina.

Fiber laser passes through the cornea and lens focus to the retina

2015年3月25日星期三

Manufacture and Supply High Quality CVDZnSe Meniscus Co2 Laser Focus Lens

2015 Year Hottest Sell ZnSe Meniscus Co2 Laser Focus Lens D20mm

Laser lenses are used in most CO2 laser systems to focus all the beam’s power into a very small spot. Small, focused spot size is important for a couple of reasons: cutting, welding and heat treating generally call for high-power density, and power density is a strong function of spot size. (Reduce the spot diameter by 50% and the power density increases by 200%.) Also, many jobs demand narrow kerf widths and heat affected zones, which can only be achieved with a tightly focused beam.

The design variables that will affect the performance of a CO2 laser lens are: Lens material, focal length, diameter, shape, material and coating.

Specifications:

Product: co2 laser focus lens

Material: CVD ZnSe

Design Wavelength: 10.6 um

Focal Length Tolerance: ±1%

Diameter Tolerance: +0.0 / -0.12 mm

Thickness Tolerance: ±0.2 mm

Surface Accuracy:

Surface Quality: 20-10 scratch and dig

Centration: <3' arc minutes

Clear aperture: >90%

Beveling: <0.2 x 45°

AR/AR Coating: R<0.5% per surface @10.6um

Focal Length

Focal length affects both spot size and depth of focus. In general, a shorter focal length will produce a smaller focused spot and a shorter depth of focus. Usually, the specified focal length is a compromise between desired spot size, penetration depth and workpiece clearance.

Lens Diameter

Higher power lasers require larger diameter lenses to prevent thermal overload. At any given focal length, a larger diameter lens will yield a smaller focused spot if the incoming beam is expanded to fill the larger lens.

Lens Shapes

Plano-convex is the simplest and least expensive lens shape. It is used in such applications as welding where achieving the smallest spot size is not critical, or at relatively long focal lengths when more complex shapes would not be beneficial. A plano-convex lens should be oriented with the flat side toward the workpiece and the convex side toward the laser. Meniscus lenses have a concave curve on one side and a convex curve on the other. At relatively short focal lengths, a meniscus lens will yield a smaller focused spot than a plano-convex lens. However, meniscus lenses are more expensive to manufacture than plano-convex lenses because both sides are curved. A meniscus lens should be oriented with the concave curve toward the workpiece.

Why you choose SPT co2 Laser focus lens?

1. SPT co2 laser focus lens is made of high purity USA CVD ZnSe, which is from DOW chemical, the largest lens material supplier in the world. Co2 laser lens made from high quality ZnSe comes with very high light transmittance which won't weak your laser power when laser light goes through it.

2. All SPT laser co2 laser lens is made in Meniscus shape, which has much better focusing effect than cheaper plano-convex co2 laser lens. Meniscus shape lens will enhance your laser power to help you get faster cutting speed.

3. To assure laser lens quality, SPT laser send their laser lens to the USA or Singapore for coating. So the coating film on our lens won't come off, this promises your co2 laser lens lifetime.

Co2 laser lens parameters for you to choose:

Pls send your inquiry to: dgspt@laserwd.com

Click here to know more about SPT Laser:

https://www.facebook.com/dongguanspt?ref=notif¬if_t=page_new_likes

Laser lenses are used in most CO2 laser systems to focus all the beam’s power into a very small spot. Small, focused spot size is important for a couple of reasons: cutting, welding and heat treating generally call for high-power density, and power density is a strong function of spot size. (Reduce the spot diameter by 50% and the power density increases by 200%.) Also, many jobs demand narrow kerf widths and heat affected zones, which can only be achieved with a tightly focused beam.

The design variables that will affect the performance of a CO2 laser lens are: Lens material, focal length, diameter, shape, material and coating.

Specifications:

Product: co2 laser focus lens

Material: CVD ZnSe

Design Wavelength: 10.6 um

Focal Length Tolerance: ±1%

Diameter Tolerance: +0.0 / -0.12 mm

Thickness Tolerance: ±0.2 mm

Surface Accuracy:

Surface Quality: 20-10 scratch and dig

Centration: <3' arc minutes

Clear aperture: >90%

Beveling: <0.2 x 45°

AR/AR Coating: R<0.5% per surface @10.6um

Lens

Material:

CVDZnSe is the most popular optical material

used for producing co2 laser focus lens. It has very high light transmittance

which can assure the smallest power wastage during tansmission. Due to different

procedure, we can get PVDZnSe and CVDZnSe. Much less impurity makes CVDZnSe

becomes the most popular raw material for making co2 laser lens.

Focal Length

Focal length affects both spot size and depth of focus. In general, a shorter focal length will produce a smaller focused spot and a shorter depth of focus. Usually, the specified focal length is a compromise between desired spot size, penetration depth and workpiece clearance.

Lens Diameter

Higher power lasers require larger diameter lenses to prevent thermal overload. At any given focal length, a larger diameter lens will yield a smaller focused spot if the incoming beam is expanded to fill the larger lens.

Lens Shapes

Plano-convex is the simplest and least expensive lens shape. It is used in such applications as welding where achieving the smallest spot size is not critical, or at relatively long focal lengths when more complex shapes would not be beneficial. A plano-convex lens should be oriented with the flat side toward the workpiece and the convex side toward the laser. Meniscus lenses have a concave curve on one side and a convex curve on the other. At relatively short focal lengths, a meniscus lens will yield a smaller focused spot than a plano-convex lens. However, meniscus lenses are more expensive to manufacture than plano-convex lenses because both sides are curved. A meniscus lens should be oriented with the concave curve toward the workpiece.

Why you choose SPT co2 Laser focus lens?

1. SPT co2 laser focus lens is made of high purity USA CVD ZnSe, which is from DOW chemical, the largest lens material supplier in the world. Co2 laser lens made from high quality ZnSe comes with very high light transmittance which won't weak your laser power when laser light goes through it.

2. All SPT laser co2 laser lens is made in Meniscus shape, which has much better focusing effect than cheaper plano-convex co2 laser lens. Meniscus shape lens will enhance your laser power to help you get faster cutting speed.

3. To assure laser lens quality, SPT laser send their laser lens to the USA or Singapore for coating. So the coating film on our lens won't come off, this promises your co2 laser lens lifetime.

| |

Dia (mm) |

Focus

Length |

Thickness (mm) |

Model No. | Dia (mm) |

Focus

Length |

Thickness (mm) |

| SPT12.7-2.0-1.8 | 12.7 | 50.8 | 1.8 | SPT20.0-3.0-2.0 | 20 | 76.2 | 2.5 |

| SPT14.5-1.5-1.8 | 14.5 | 38.1 | 1.8 | SPT20.0-4.0-2.0 | 20 | 101.6 | 2.5 |

| SPT14.5-2.0-1.8 | 14.5 | 50.8 | 1.8 | SPT1.0''-2.0-3.0 | 25.4 | 50.8 | 3.0 |

| SPT15.26-1.5-1.8 | 15.26 | 38.1 | 1.8 | SPT1.0''-2.5-3.0 | 25.4 | 63.5 | 3.0 |

| SPT16.0-1.5-2.0 | 15.26 | 38.1 | 2.0 | SPT1.0''-3.0-3.0 | 25.4 | 76.2 | 3.0 |

| SPT16.0-2.0-2.0 | 15.26 | 50.8 | 2.0 | SPT1.0''-4.0-3.0 | 25.4 | 101.6 | 3.0 |

| SPT18.0-1.5-2.0 | 18 | 38.1 | 2.0 | SPT1.0''-5.0-3.0 | 25.4 | 127 | 3.0 |

| SPT18.0-2.0-2.0 | 18 | 50.8 | 2.0 | SPT1.1''-2.0-3.0 | 27.94 | 50.8 | 3.0 |

| SPT18.0-2.5-2.0 | 18 | 63.5 | 2.0 | SPT1.1''-2.5-3.0 | 27.94 | 63.5 | 3.0 |

| SPT18.0-3.0-2.0 | 18 | 76.2 | 2.0 | SPT1.1''-3.0-3.0 | 27.94 | 76.2 | 3.0 |

| SPT18.0-4.0-2.0 | 18 | 101.6 | 2.0 | SPT1.1''-4.0-3.0 | 27.94 | 101.6 | 3.0 |

| SPT19.05-1.5-2.0 | 19.05 | 38.1 | 2.0 | SPT1.1''-5.0-3.0 | 27.94 | 127 | 3.0 |

| SPT19.05-2.0-2.0 | 19.05 | 50.8 | 2.0 | SPT1.5''-3-4.0 | 38.1 | 76.2 | 4.0 |

| SPT19.05-2.5-2.0 | 19.05 | 63.5 | 2.0 | SPT1.5''-5-4.0 | 38.1 | 127 | 4.0 |

| SPT19.05-3.0-2.0 | 19.05 | 76.2 | 2.0 | SPT1.5''-7.5-4.0 | 38.1 | 190.5 | 4.0 |

| SPT19.05-4.0-2.0 | 19.05 | 101.6 | 2.0 | SPT1.5''-5-0.31'' | 38.1 | 127 | 7.87 |

| SPT20.0-1.5-2.0 | 20 | 38.1 | 2.0 | SPT1.5''-7.5-0.31'' | 38.1 | 190.5 | 7.87 |

| SPT20.0-2.0-2.0 | 20 | 50.8 | 2.2 | SPT1.5''-5.0-0.35'' | 38.1 | 127 | 9.00 |

| SPT20.0-2.5-2.0 | 20 | 63.5 | 2.2 | SPT1.5''-7.5-0.35 | 38.1 | 190.5 | 9.00 |

Pls send your inquiry to: dgspt@laserwd.com

Click here to know more about SPT Laser:

https://www.facebook.com/dongguanspt?ref=notif¬if_t=page_new_likes

Most Durable co2 laser machine Linear Guide Rail SPT1390

Check more details here about this product

http://www.alibaba.com/product-detail/Most-Durable-co2-laser-machine-Linear_60200696549.html

2015 Year D.PES Sign Expo Hot sell SPT LASER long lifetime co2 laser tube 90w

Co2 laser tube is the most important part to co2 laser

cutting machine, it decides the laser cutting speed and cutting performance. It

is actually sealed glass co2 laser tube, we usually call it " laser tube" or co2

laser tube. It is combined with 3 main parts: hard glass tube, cavity resonator

and electrode parts. The most common model in the market now is 30w, 40w, 50w,

60w, 80w, 100w, 130w, and 150w co2 laser tube. Laser power is the mainly index

for us to tell different co2 laser tubes, and the most simple way for us to tell

different power co2 laser tube is the laser tube length, since laser tube length

matters most to the power a laser tube can reach to. Co2 laser tube is mainly

installed onto co2 laser machines, such as co2 laser cutting machine, co2 laser

engraving machine and co2 laser marking machine.

SPT Laser 90w co2 laser tube detail

Check out more details here:

http://www.alibaba.com/product-detail/2015-Year-D-PES-Sign-Expo_60200740535.html

To know more about SPT Laser, welcome to visit:

https://www.facebook.com/dongguanspt?ref=notif¬if_t=page_new_likes

SPT Laser 90w co2 laser tube detail

| Model | C90-90W laser tube |

| Length | 1250mm |

| Pipe Diameter | 80mm |

| Wavelength | 10.6um |

| Beam Divergence Angle | 3.1mrad |

| Light Beam Quality | ≤1.1 |

| Stability | 10% |

| Output Power Stable Value | 90W |

| Max Output Power | 100W |

| Fai Voltage | 20KV |

| Working Voltage | 15KV |

| Triggering Current | 5.0mA |

| Max Working Current | 35mA |

| Spot Diameter | 4±1 mm |

| Available cutting material | Acrylic, leather, fabric, paper, wood, etc |

| Available laser machine | CO2 laser cutting machine and engraving machine |

| Available industry | Advertising, shoe making, handbag making, furniture, beauty, etc. |

Check out more details here:

http://www.alibaba.com/product-detail/2015-Year-D-PES-Sign-Expo_60200740535.html

To know more about SPT Laser, welcome to visit:

https://www.facebook.com/dongguanspt?ref=notif¬if_t=page_new_likes

2015年3月19日星期四

SPT Laser---- Got a complete success at 2015 Guangzhou D.PES LED & Sign expo

2015年2月6日星期五

Co2 laser in the carton packaging industry

We all know that the co2 laser has been widely used for cutting/ engraving acrylic,

cloth, leather, wood and other non-metal materials. Due to high efficiency and

high precision of process, co2 laser is very popular in today's advertising

industry as well as clothing, footwear and other industries. In fact, co2 laser

also contributes a lot to the packaging industry, and the packaging industry is

one of the earliest industries adopt co2 laser into production.

1. Corrugated case printing plate

The most common packaging is corrugated case in the printing and packaging industry. Corrugated boxes can be divided into two categories, one is the sales package, and the other is the transport package. Sales package is generally for inner-packing, used in the sales process to meet with consumers, such as color box, white box, gift boxes. Transport packages are outer-packing, and its main role is to facilitate the storage and transportation, such as cardboard boxes, corrugated boxes and so on.

Laser engraving machine achieves carving by doting on material surface, has a born advantage in grayscale performance. So in the carving design, gray level appearance form is very popular to reduce the coloring process to cut costs; on the one hand, it enriches the carving performance, increases graphical levels. Meanwhile, the cost of printing plate for engraving on paper packaging materials made by co2 laser is very low, only a quarter of resin version, so co2 laser engraving plate is commonly used as corrugated packaging printing mode in packing industry nowadays.

1. Corrugated case printing plate

The most common packaging is corrugated case in the printing and packaging industry. Corrugated boxes can be divided into two categories, one is the sales package, and the other is the transport package. Sales package is generally for inner-packing, used in the sales process to meet with consumers, such as color box, white box, gift boxes. Transport packages are outer-packing, and its main role is to facilitate the storage and transportation, such as cardboard boxes, corrugated boxes and so on.

Laser engraving machine achieves carving by doting on material surface, has a born advantage in grayscale performance. So in the carving design, gray level appearance form is very popular to reduce the coloring process to cut costs; on the one hand, it enriches the carving performance, increases graphical levels. Meanwhile, the cost of printing plate for engraving on paper packaging materials made by co2 laser is very low, only a quarter of resin version, so co2 laser engraving plate is commonly used as corrugated packaging printing mode in packing industry nowadays.

2. Die-cutting board making

Die-cutting is cutting process crates, boxes before molding, with the cutting knife combined to die - according to product design requirements, under pressure, and will print or other plate-blank roll and cut into desired shapes or cuts in the molding process. With the rapid development of world economy, the increased demand packing boxes, plate-making process improvement, higher quality requirements, the product of small batches of multi-volume, problems about shorten delivery time and cost increases and other issues show up, the traditional manually cutter template box making process can’t meet these market needs and solve coming problems. Because of high efficiency, high accuracy, low cost, flexible production and operability, laser processing rapidly rises up and being widely used in the packaging industry. Co2 laser die-cutting machine ablates die-board in high depth with its high heat to get cutter point. This makes die-cutting board has slotted collimation, consistent slit width. Co2 laser die-cutting process is fully automated operation, has fast delivery, high efficiency, low cost, it is the best alternative to manual work production of precision cutting board.

In addition, co2 laser processing also affects and enriches the diversity and practicality on other aspects in packing industry. Co2 laser used to mark products, logos, bar codes, or other markings printed on the product packaging, which enhances the richness of information on package, to better highlight the brand. Other important applications include the plastic packaging punch to extend the shelf life of food perishable; or in the paper packaging, cardboard, or plastic wrap advance left tear, these applications are extremely convenient for consumers as well as bring more invisible benefits for suppliers. We believe that with the rapid changes in technology, co2 laser will surprise us more with its applications in packing business.

How to tell good co2 laser tube?

There are so many co2 laser tubes available

in the market and everybody is saying that our co2 laser tube is the best

quality. I am sure you are tired of this and sometimes don’t know what to do.

Should I buy the cheapest one? Anyway, it is not expensive, it’s not a big deal

even the quality is bad. How about the most expensive one? I don’t want to

waste my money and time, just need the right thing. Or maybe I should choose

the middle-price rated one? It seems more price-competitive. I am sure you went

through one of those situations, maybe more than this? SPT laser is here to guide

you how to tell good laser tube by some simple means. And also this is how SPT

laser picks good laser tubes when sending your laser tube orders.

First you have to install your laser tube

well, connect it to the water chiller (chiller pump), and get it wire

connected. Then do the following steps.

1.

Get laser spot. Set the current at 10mA,

do the test as following steps at 0.5~2m away from the laser tube negative end:

Fire a spot on the card board,

and check the shape of the spot.

A: The spot is a

very good solid round, the laser tube is good.

B: The spot is

an oval, please check if the laser tube is put on the tube support at the best

laser tube support point.

C: The spot is a

circle, please check if the tube supports is at the best laser tube support

point, and the testing distance is between 0.5 and 2.0m. If the support point

and test distance both are right, the laser tube is bad.

Good laser spot Bad laser spot

Fire a spot on thermal

paper,

A: The inner and outline of the spot is parallel regular

circle, the laser tube is good.

B: The inner and outline of the spot is irregular, the

laser tube is bad.

Good laser spot

Bad laser spot A Bad laser spot B

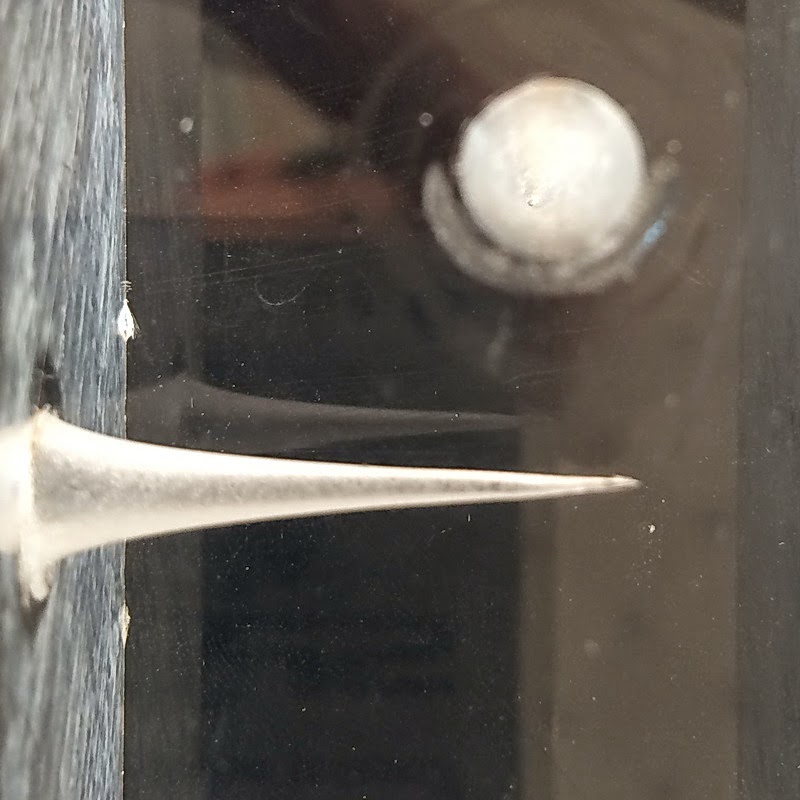

Laser spot mode test: Put a 40mm thick acrylic at the point where is

1.2m~1.5m away from the laser tube negative end.

Adjust the current to 20mA~25mA, push the laser button, let the

laser fire on the acrylic for seconds. You will get a conic hole on the acrylic.

If the conic is very round and regular, the laser tube is good.

Fire a spot on acrylic:

A, The laser

spot is a solid circle, the laser tube is good.

B, The laser

spot is an irregular round, and the tube supports are at right support point,

test distance is also correct, the laser tube is bad.

2.

Laser power test: Under rated current,

if the laser tube peak power is more than its rated power by 10W, the laser

tube is good. Those are the laser tube model and basic parameters of SPT laser

tube for your reference:

Item

|

Product

|

Series

|

Model

|

Current

( mA)

|

Rated Power

(Watt)

|

Peak Power

( Watt)

|

Length

(mm)

|

Pipe diameter

(mm)

|

Catalytic

(Y/N)

|

A001

|

Co2 laser tube

|

G series

|

G40

|

15

|

40

|

50

|

700

|

50

|

N

|

A002

|

Co2 laser tube

|

G50

|

15

|

50

|

60

|

1000

|

50

|

N

|

|

A003

|

Co2 laser tube

|

G60

|

20

|

60

|

70

|

1200

|

50

|

N

|

|

A004

|

Co2 laser tube

|

G70

|

20

|

60

|

70

|

1250

|

55

|

N

|

|

A005

|

Co2 laser tube

|

G80

|

20

|

80

|

100

|

1600

|

60

|

N

|

|

A006

|

Co2 laser tube

|

C series

|

C40

|

15

|

40

|

50

|

800

|

80

|

Y

|

A007

|

Co2 laser tube

|

C50

|

15

|

50

|

70

|

1000

|

50

|

Y

|

|

A008

|

Co2 laser tube

|

C60

|

20

|

60

|

80

|

1200

|

50

|

Y

|

|

A009

|

Co2 laser tube

|

C70

|

20

|

60

|

80

|

1250

|

55

|

Y

|

|

A010

|

Co2 laser tube

|

C80

|

25

|

100

|

120

|

1600

|

60

|

Y

|

|

A011

|

Co2 laser tube

|

C90

|

25

|

90

|

100

|

1250

|

80

|

Y

|

|

A012

|

Co2 laser tube

|

C100

|

25

|

100

|

130

|

1450

|

80

|

Y

|

|

A013

|

Co2 laser tube

|

C130

|

25

|

130

|

150

|

1650

|

80

|

Y

|

|

A014

|

Co2 laser tube

|

C150

|

30

|

150

|

180

|

1850

|

80

|

Y

|

|

A015

|

Co2 laser tube

|

S series

|

S90

|

25

|

90

|

100

|

1250

|

80

|

Y

|

A016

|

Co2 laser tube

|

S100

|

25

|

100

|

130

|

1450

|

80

|

Y

|

|

A017

|

Co2 laser tube

|

S130

|

25

|

130

|

150

|

1650

|

80

|

Y

|

|

A018

|

Co2 laser tube

|

S150

|

30

|

150

|

180

|

1850

|

80

|

Y

|

订阅:

评论 (Atom)